Spring mix is the term given to a variety of different packaged salad products. In general, spring mix usually contains tender baby lettuce, spinach, and other edible leaves. It may also include red and green romaine, red and green oak leaf, chard, arugula, spinach, endive, radicchio, and other heirloom lettuces. The exact content of the mix will impact its flavor profile.

Spring Mix

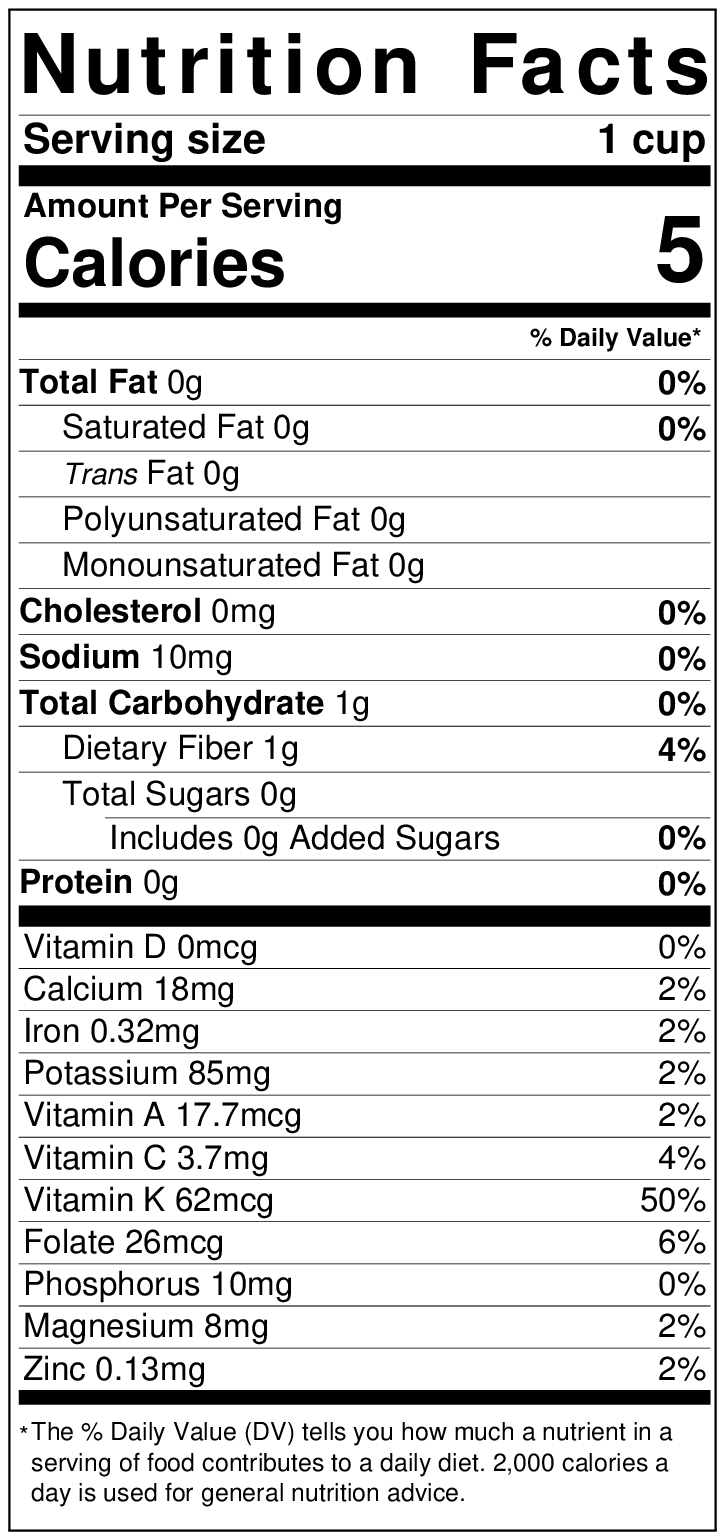

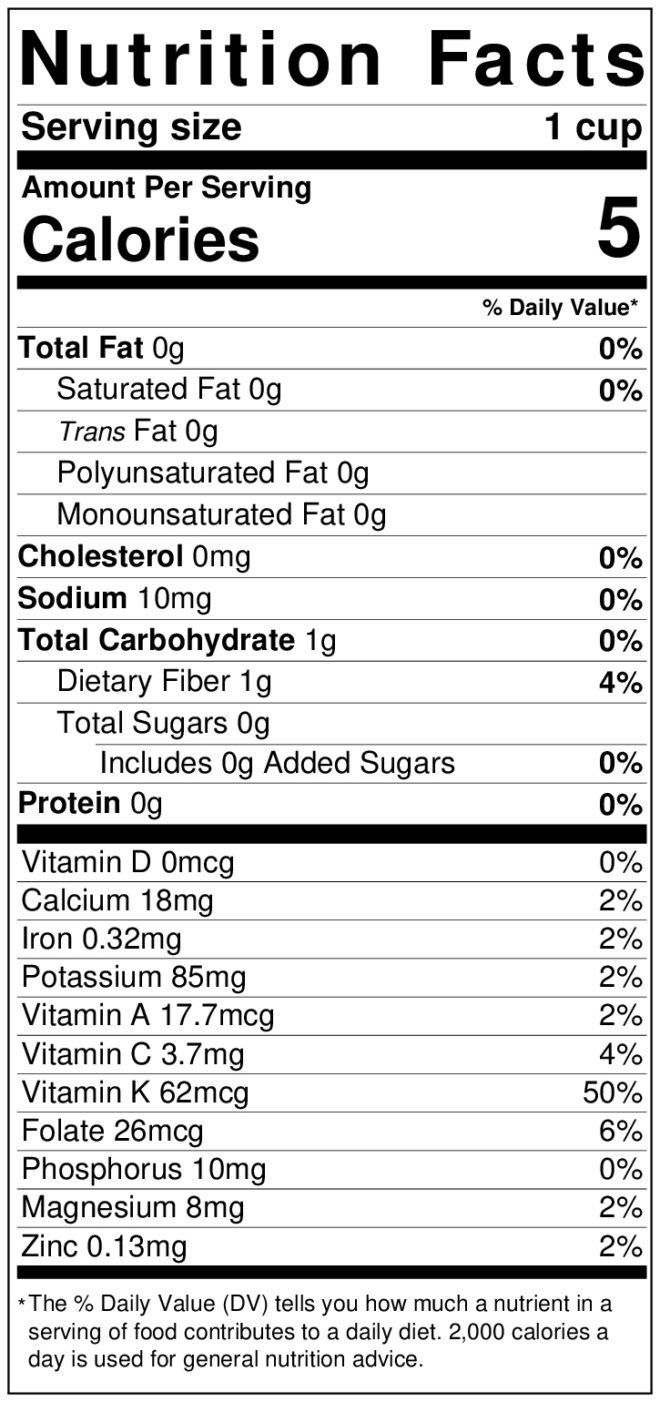

Spring Mix Nutrition Facts

- Spring Mix provides an:

- Excellent source of vitamin K

- Folate

Growing Information

Spring mix is normally harvested mechanically at a very young age, before they reach five inches in height. It’s often harvested at night when temperatures are cooler, the air is still and there is less humidity, which allows the greens to stand up making them easier to cut. The mechanical harvesting equipment uses a horizontal saw blade that cuts the leaves at the base. The height of the blade is adjustable. The cut leaves are carried on a conveyor belt to an air gap, where heavier contaminants such as weeds or debris will fall through. The young spring mix leaves fall onto a secondary conveyor belt and are transferred into a bulk harvest bin.

Usage Ideas

Salad is the perfect thing for Spring Mix since it already has a variety of greens and is normally sold pre-washed and packaged

Spring Mix Salad

Spring Mix Salad

Stay in the Know About Lettuce

Sign up for Health & Safety Alerts

Get the facts about lettuce and why it’s one of the safest and healthiest foods we can eat.